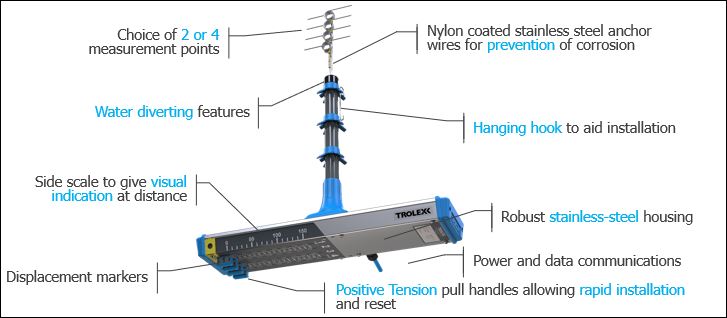

Trolex has been known for its innovative solutions in hazardous environments for over 60 years, including particulate monitoring and gas detection. In partnership with Australian company Nome Services, Trolex launched the Rock Monitor XR, an intrinsically safe monitoring solution for roof-bolted underground roadway strata. This fully networked solution measures the displacement of roof strata and sidewall strata, and can be used in soft rock applications as well.

Flotation 360 solution

An optimized flotation circuit can positively impact valuable product recovery and grade. The Flotation 360 solution from Nalco Water combines chemistry, technical service, actionable advisories, and digital technology to maximize flotation performance and recovery. The Flotation 360 solution is comprised of advanced collectors and digital diagnostic tools. The services of a global network of service engineers monitor performance indicators and recommend changes to the client’s system to ensure maximum flotation efficiency and performance.

Nalco Water is a global provider of advanced chemistry and service for the mining and processing industries. The Flotation 360 solution utilizes advanced chemistries and a global network to offer comprehensive flotation solutions for mining and processing operations. It reduces water usage and helps control moisture and dust in strip coal. A Flotation 360 solution can improve productivity, reduce costs and troubleshooting, and increase product quality and smelter compliance.

Dust suppression solutions

In order to reduce airborne dust in a mine, you must have effective dust suppression solutions for rock monitor operations. The most common solution is using water to wet the surface of the material. This will prevent fugitive dust particles from settling to the ground. Wet dust suppression equipment works by wetting the cargo surface with a misting system. This equipment uses a proprietary mixture of non-ionic surfactants, alcohols, and nano-polymers to reduce surface tension. Water and dust particles will be captured by the water particles.

To comply with environmental standards, mine operators must measure dust emissions and upload them to the EPA’s website. Dust is a big problem in the mining industry. Dust can lead to various diseases, including pneumoconiosis and black lung. To reduce the impact of dust on the health of workers, governments have put in place dust emission standards. In Australia, the EPA has implemented rules and regulations for mining companies that must meet these standards.

Intelligent strata monitoring system

An intelligent strata monitoring system can be a crucial part of your construction project. These devices are easy to install and read, robust, and durable. This type of monitoring equipment can give geotechnical engineers critical information needed for project planning. They can even monitor the support structures of a roadway, ensuring a safe, reliable, and productive project. With the help of this monitoring system, you can avoid costly downtime and ensure your construction project is successful.

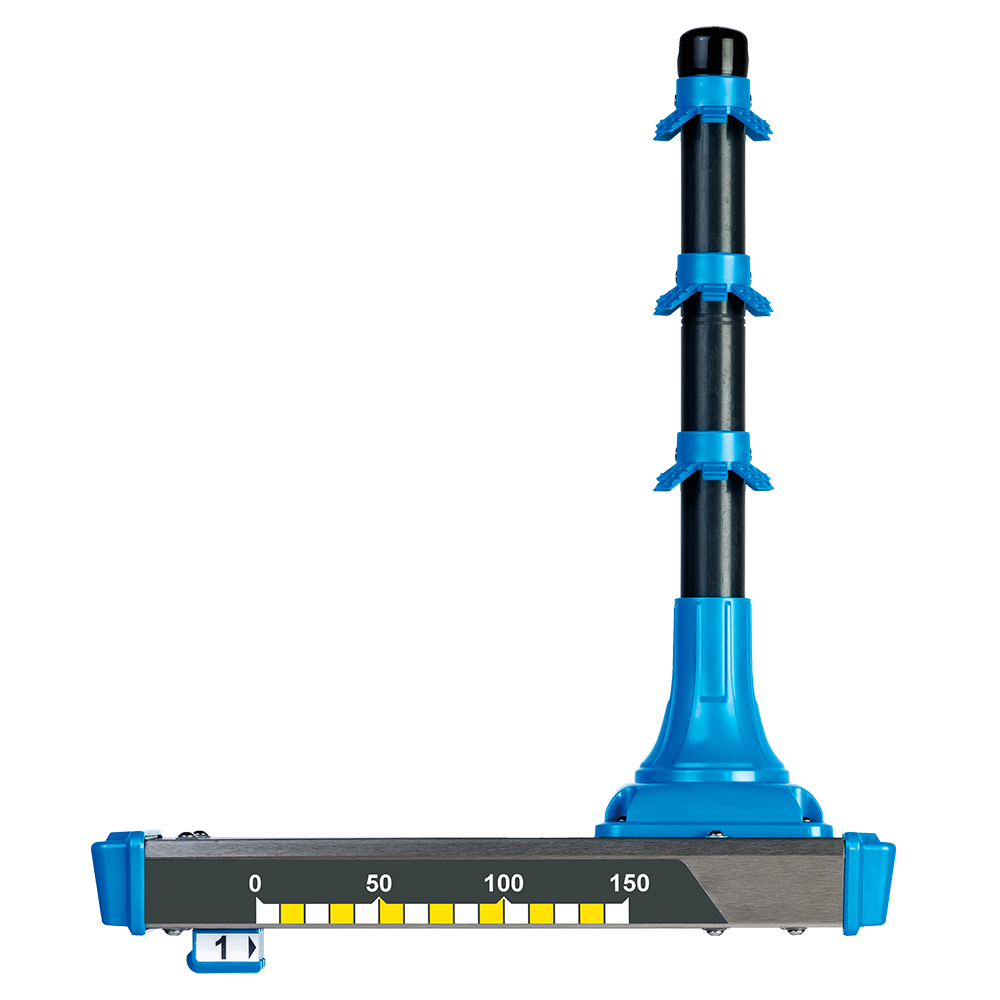

The Nome Services Rock Monitor XR is a fully networked monitoring system for roof-bolted strata in underground roadways. The system uses advanced firmware algorithms to provide real-time information about strata stability, reducing downtime and increasing productivity. The Nome Rock Monitor XR telltale incorporates a comprehensive data collection system and has a high-quality design. It can even connect to a computer network.

Nalco Water’s RockMonitor XR

Nome Services’ RockMonitor XR is a networked strata monitoring system that offers real-time data about the stability of roof bolted strata. The unit’s high-quality design and advanced firmware algorithms provide reliable strata control monitoring and reduce downtime. Nome Services’ RockMonitor XR telltale has multiple uses for underground pipelines, including roadways.

The RockMonitor XR is an intrinsically safe system designed for roof-bolted underground roadway strata monitoring. This system is fully networked and allows for measurement of strata displacement in soft rocks and hard rock. Using the RockMonitor XR will reduce the amount of water needed for dust control and moisture control in the strip coal. A complete process water monitoring solution is available to improve safety, improve efficiency and reduce cost.

Nome Services – Resmesh

Nome Services has designed a unique roof safety mesh that minimises acidic reactions which can deteriorate roofing support systems. This resin-coated steel mesh has a lifespan of 20 years and can be used in highly corrosive environments. To read more about the roof-safety-mesh, visit the Nome Services website. Here you can find more information about roof safety mesh, including its benefits and advantages.

Resin coated steel mesh

Resin coated steel mesh is used in mines for several reasons, including to provide a safe working environment and to provide roof support. Its design minimizes the formation of acidic reactions, which can weaken roof support systems. Moreover, it can last more than 20 years, making it an excellent choice for mining facilities. Listed below are the pros and cons of Resmesh and how to use it in mines.

Galvanised steel mesh

The installation of roof safety mesh is vital to the health and safety of your workers. In addition to providing a safe working environment, roof safety mesh also protects the surrounding structure from damaging acidic reactions, which can weaken roof support systems. Galvanised steel mesh is available in various sizes, wire gauges, and spacings. Nome Services recommends Resmesh for corrosive environments.

The Safety Mesh system provides permanent protection from fall hazards and injury during roof installation and maintenance. Made of two-millimetre-thick galvanised steel wire with a tensile strength of 450 MPa, Safety Mesh is a tested supporting member that must remain in place during fall protection. It also conforms to the Approved Code of Practice for Safety in Working at Heights.

The safety mesh is fixed to a supporting member, such as purlins, rafters, or bridge bars. It also controls the risk of falling during the insulation installation of roof insulation. It is also useful for penetrations and control of fall hazards across the entire roof area. Depending on the thickness of the roofing material, a mesh is adjustable and can be fixed to timber roof members or a variety of other structures.